The HydraulikBiber

Mode of operation

No excavation pit needs to be dug for the HydraulikBiber and adjacent areas are not endangered.

Disruptive superficial lateral roots can be easily cut and then levered out with the HydraulikBiber.

The HydraulikBiber is portable and works in a minimally invasive way.

Currently stumps that need to be cleared after felling trees are usually milled or excavated. While large tillers offer fast progress and are comfortable to operate, they often cannot reach the site at all. Smaller tillers, on the other hand, often have problems milling larger or harder rootstocks and offer only a shallow milling depth and slow progress. What all tillers have in common is that they can throw stones around, are very noisy, generate a lot of dust in dry soil and require a lot of energy.

Excavators do not have these problems and excavator-guided grubbers can grub efficiently even in the lower weight classes, but they often leave a lot of damage in the garden, are expensive and still cannot reach many stumps in the first place.

The HydraulikBiber works gently and cheaply.

Due to its low wear, the energy-saving mode of operation and the compact design, only very low operating and logistics costs are incurred, comparable to a small hydraulic log splitter. This, combined with its favorable price and ease of operation, makes the HydraulikBiber affordable and useful even for small businesses.

Technology

Work smart, not hard.

The idea behind the HydraulikBiber is to chip the tree stump with slow, powerful movements instead of high cutting speed, just like an excavator-guided clearing knife. Our hand-guided device avoids the disadvantages of milling (high wear, skidding effect) and excavating (cost, lack of flexibility, invasive technology, logistics).

The HydraulikBiber offers a lot of power in a small space.

It works with a pincer that makes it possible to develop a sufficiently high cutting force with a large opening width and that is at the same time light and compact enough to be operated by one person.

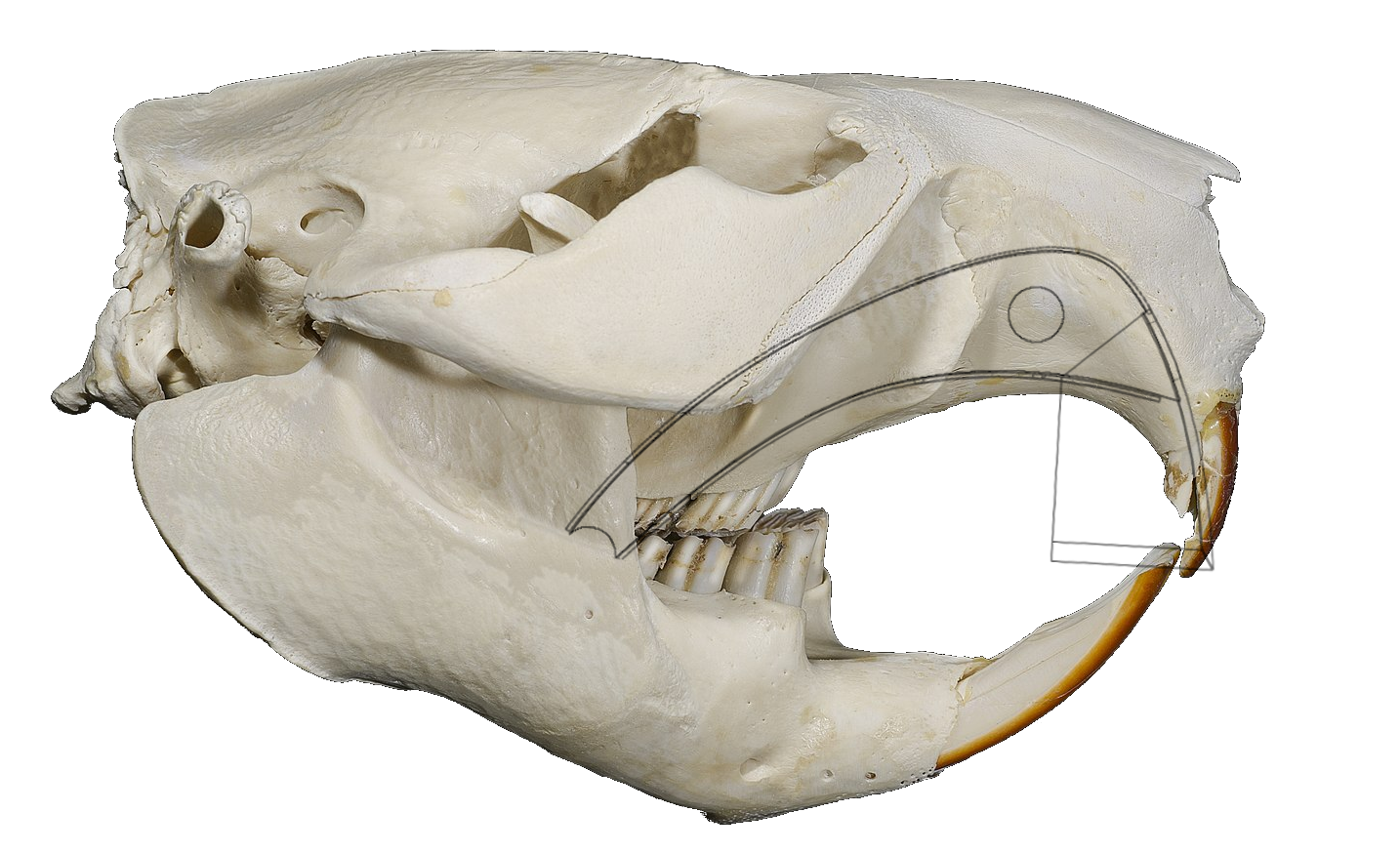

For this purpose, we have developed the geometry of the HydraulikBiber, which is based on a beaver jaw. The hydraulic cylinder works - similar to a jaw muscle - via pulling rather than pushing force and is positioned between the carrying arches of the tongs. This makes the compact design and the excellent force-to-weight ratio of our HydraulikBiber possible.

The HydraulikBiber uses intelligent shapes down to the last detail.

Its cutting geometry makes it possible to cut off the entire chip in one go, regardless of the shape and grain of the stump to be processed, since it is usually not possible to pull the HydraulikBiber out of the rootstock again and reattach it using physical force once it has been attached.

This was achieved by the patent-pending L-cut geometry of the blades. Similar to a planing tooth of a saw chain, it enables all fibers to be cut regardless of the course of the wood fiber, thus always enabling the chip to be ejected.

Video Tutorial